On my recent trip to Oregon I tried to take a balanced approach to exploring breweries. I wanted varied perspectives on the craft, styles, and goals of each operation. The choices included small operations working out of basements and brewing giants managing colossal facilities. I arranged my first tour at the Deschutes Brewery, a monolith of Bend beer production. As of 2009, they’re the largest producer in Oregon (69,649 barrels) and thirteenth in the United States.

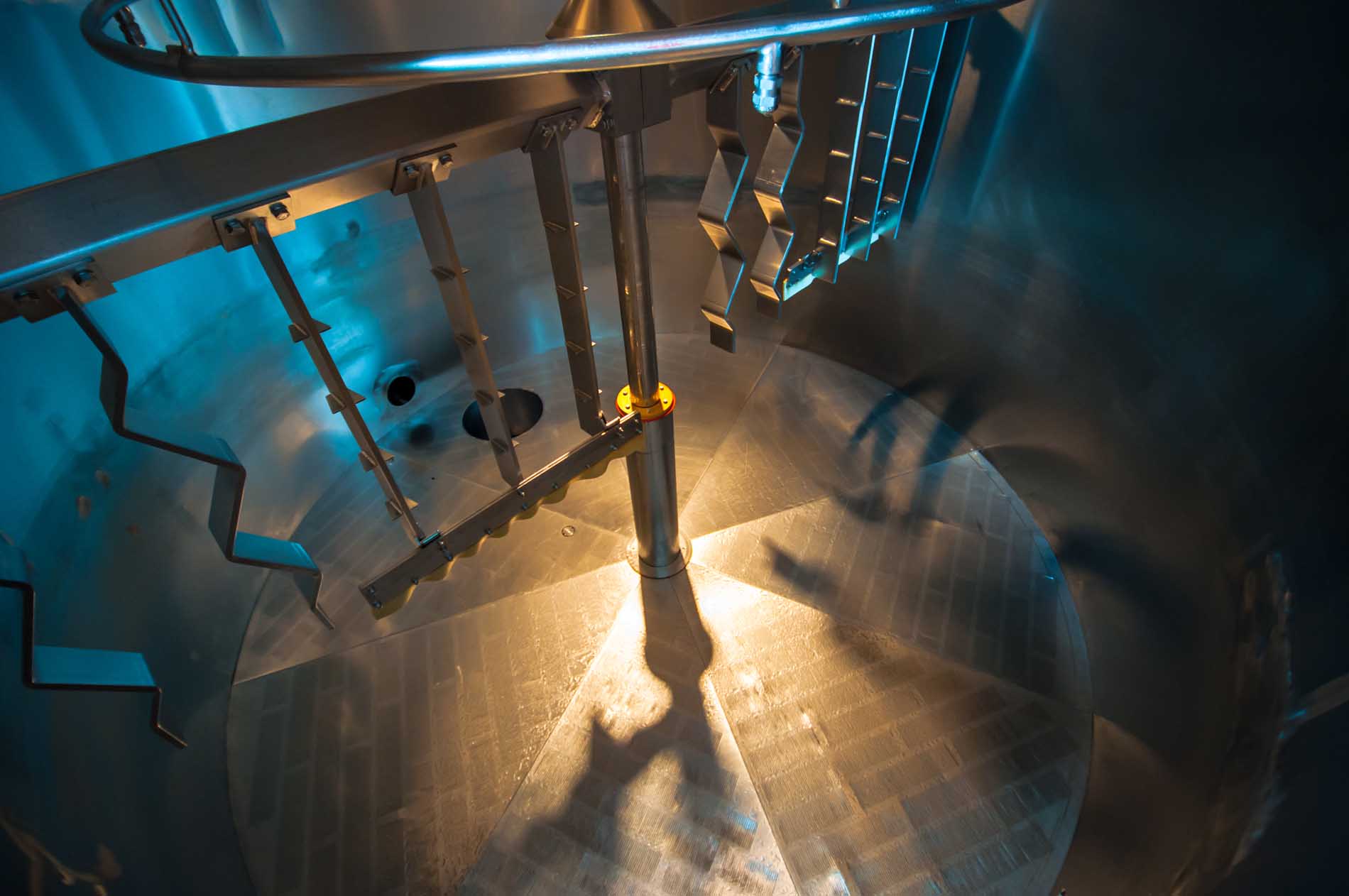

The brewery anchors a traffic circle in a modern industrial neighborhood south of downtown. A series of expansions has nearly tripled the size of operations since production started at the current location in 1993. The facility houses their original 50-barrel gravity flow system and a German designed Huppman system that can handle 131 barrels. The output feeds current demand throughout the west and eastward expansion now reaches Minnesota. Nationwide distribution seems to be the current trajectory.

Before I’d even arrived in Bend I was getting negative feedback about Deschutes from several Oregonians. One waiter tried to dissuade me from drinking an Inversion IPA by saying Deschutes was getting too big. Another gentleman in Bend, who happens to work in the same industry, voiced the same complaint and thought quality was suffering as a result. I shrugged it off as a case of brand envy, especially since Deschutes took home four awards at the 2010 Great American Beer Festival.

My guide through the brewery was Aaron Calihan who worked his way up from busboy at the Deschutes Public House to overseeing tours as a Brand Ambassador. Managers felt this was a better fit since he apparently spent more time informing customers about the beer than keeping up with drink orders. He provided us with a very informative and comprehensive tour aided by elevated platforms and catwalks making it easy to see each portion of the operation from brewing to bottling.

We were also able to see a few non-manufacturing spaces that I particularly enjoyed. The aromatic hop cooler, containing whole hops and no pellets, was a wonderful sensory overload and a view of the lab, including the analytical tasting room, was very interesting. The final highlight was the employee break room where a row of taps hide behind what appears to be a restroom door. After a long shift each employee is entitled to a pint of beer. Nice perk! The taps pour standard brews along with experimental options, one of which included a refreshing wheat beer called Miss Spelt.

Upon completion of the tour I settled back into their public tasting room to try eight different beers: Mirror Pond, Green Lakes, Black Butte Porter, Cascade Ale, Oktoberfest, Twilight Summer Ale, and Black Butte XXII. The only one missing was their holiday seasonal Jubelale, which was being released later in the evening at the Public House downtown.

Overall, I enjoyed nearly every Deschutes beer. The year round releases are well balanced while the seasonal and specialty offerings are more aggressively hopped, spiked with unique ingredients, or aged in bourbon barrels producing wonderful flavor profiles. Mirror Pond has now eclipsed Sierra Nevada’s Pale Ale as my favorite in the category.

As Deschutes continues to expand it will be interesting to see how they manage the pitfalls of growth, juggle products, and maintain an intense commitment to quality. Moving into the Midwest and East Coast will also require a significant amount of cash (or credit) and the battle for shelf space between established breweries in those regions (and everywhere else for the matter) is already intense. The buy local movement also presents a challenge since its no longer just a West Coast predilection. Communities devastated by a poor economy and decades of outsourcing are finally seeing the big picture and spending their money close to home. All of this presents a formidable challenge but it’s not something a quality driven product can’t supersede.